Cost savings aren’t the only thing a company must consider when searching for the right precision machining company to work with. After all, said projects require extreme attention to detail, and the experience to match. Making decisions based purely on the pocketbook could end up harming your bottom line in ways you didn’t expect.

To choose the right precision machining company, one needs to look beyond the cost of a run, and deep into their history. Company culture, team, longevity and other criteria play a vital role in the selection process. Here’s how to choose a precision machining company based on the right criteria so you can be sure you’ll get the job done right, the first time.

EXPERIENCE IS KEY

This is perhaps the most important part of choosing the right precision machining company. This is a highly detailed and demanding field that requires a know-how of multiple industries in order to succeed. The right company will have cut their teeth on all of them, and grown throughout the years to better themselves as technologies and techniques evolve. This experience helps companies adapt on a year-by-year basis so they are always ready for the next big thing. Better yet, an experienced company can take on a brand new project run with full confidence by implementing the strategies and techniques they’ve amassed over the years. Never underestimate experience – it’s the single-most important thing to look for a great precision machining company.

CERTIFICATIONS

Precision machining companies come in different sizes, each with their own unique set of specialties. However, it’s important to make sure that your company of choice is certified to handle jobs required by particular industries such as those B.C. Instruments are involved with. These include aerospace, nuclear, plastic injection molding, electro-optic and medical. None of these industries should be taken lightly, and precision machining companies need to be fully certified in order to make sure that their project runs are up to standard, and beyond. Make sure to inquire about ISO and similar certifications to make sure you’re dealing with a reputable entity.

INTERACTION

The best companies are the ones who are easy to work with, and precision machining is no different. It’s difficult to start out on a negative note with companies who are rude, impatient or indifferent to your needs. Similarly, keep tabs on how a company communicates with you when it comes to information and requests. If they’re taking a day or two to get back to you, this could spell trouble down the road. Conversely, if they’re responding to inquiries within an hour or two, they’ve definitely got your best interests at heart. None of this is a guarantee of quality, but it’s a step in the right direction, and a good signal that you’re dealing with a company that is used to making clients happy.

LEAD TIMES

Precision machining companies need to be on the ball when it comes to lead time evaluation. Missing dates is unacceptable, and the right companies know that they have to set a mark, and work within it. This does not mean that complications won’t arise during the production run, but the best companies will utilize their experience and commitment to customer satisfaction in order to pull double duty, re-evaluate a process, or re-think the run while still committing to the original date. The best precision machining companies are the ones who sometimes deliver before the delivery date. At B.C. Instruments, we’re proud to have such a track record when committing to client satisfaction.

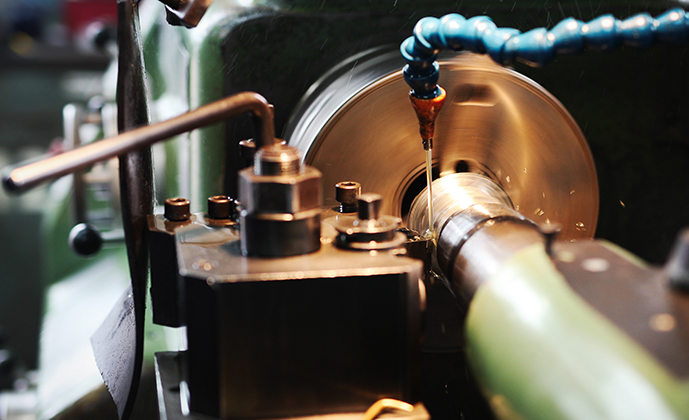

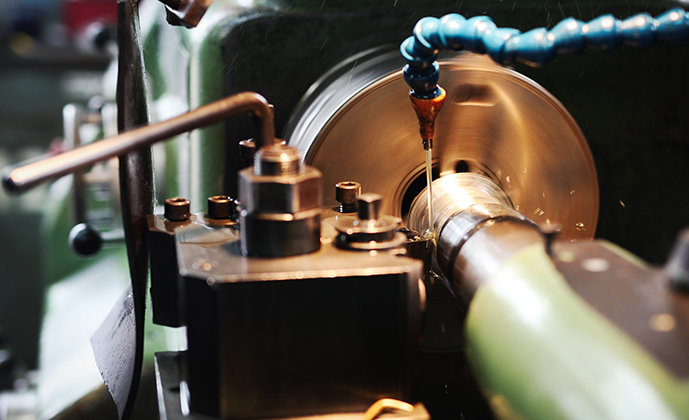

ASK ABOUT EQUIPMENT

Your particular production run might be dependent on particular tools and machinery, which is why it’s a good idea to do a deep dive into a company’s offerings. The latest technologies are nice to have, but they’re worthless if your project requires CNC machining with a particular axis, or a laser engraver that the company does not possess. Knowing what a company is using is just as important as knowing their level of experience.

Second, it’s wise to inquire about the quantity of particular machines, as well. This can make or break a deadline. When speaking to a precision machining company, analyze the projected delivery date and measure it against the amount of machines they use. If something feels sketchy, inquire further rather than signing on the dotted line.

With a little know-how, you can locate the right precision machining company to trust with your next production run. B.C. Instruments prides itself on 40+ years of top-notch surface across the most prolific industries on Earth, and we continue to grow with the times. We’re trusted by our clients for good reason, and we invite you to contact us to discuss your next project with us.