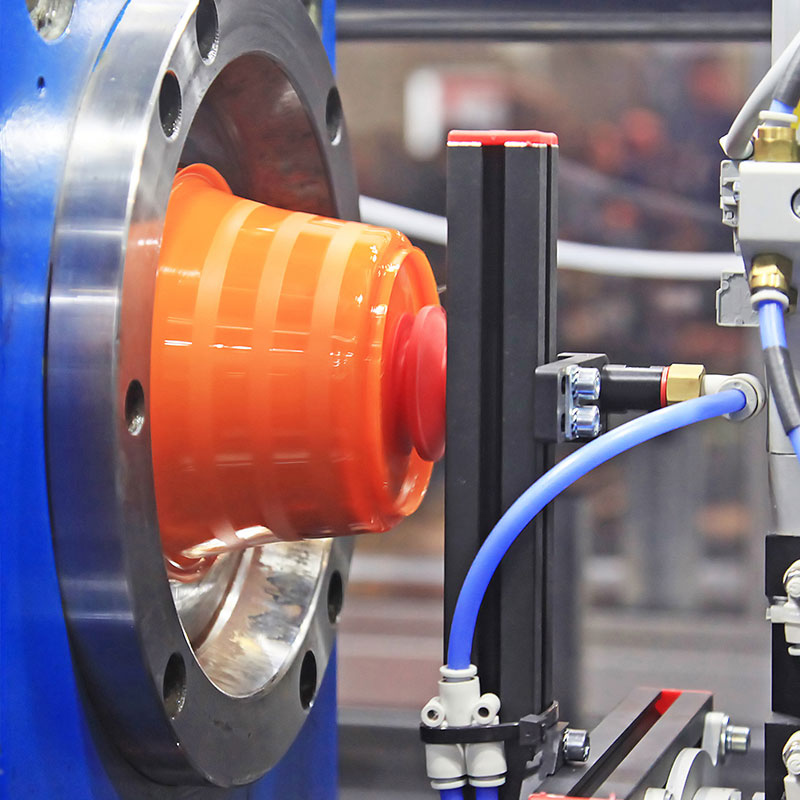

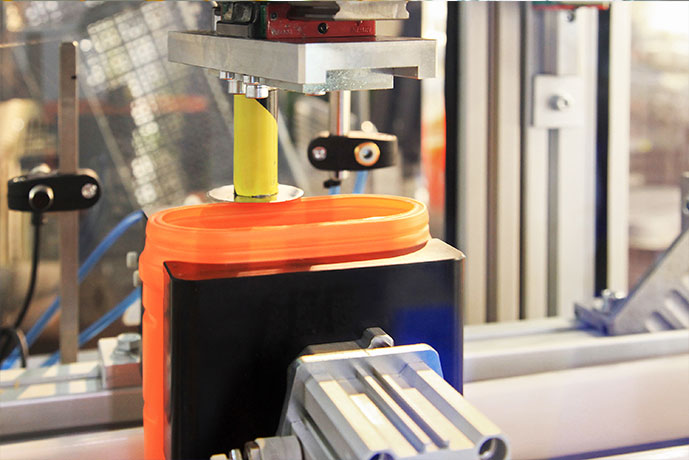

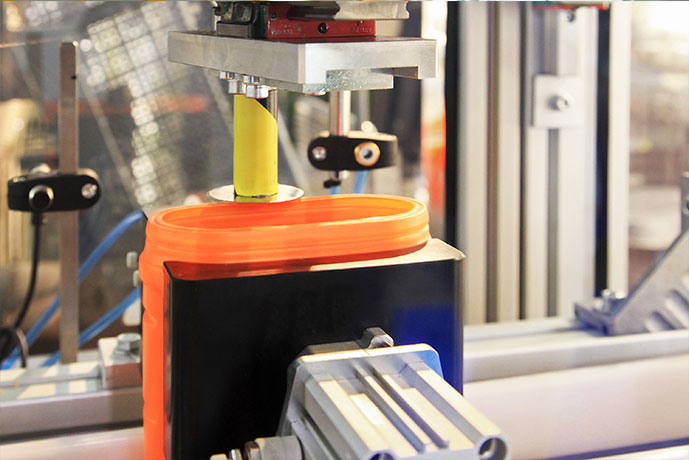

B.C. Instruments enjoys a close working relationship with clients in the engineering and product development sectors, from beta testing to mass production. Our facilities manufacture notable products including Nozzle Tips, Housings, Cooling Inserts, Pistons, Cylinders, Insulators, Manifold Brushings and MIxers, among others from the hot and cold sides of the mold. B.C. Instruments is also adept at working with Beryllium Copper, and our process have been tested and maintained under exposure limits laid down by the OHS Act.

Case Studies

Project Category: Case Studies

Western Formula Racing

Project Category: Case Studies

LONG TERM CLIENT

Project Category: Case Studies

LIBURDI

Our Memberships

Alliance for Enterprise Excellence

Our Blogs

PRECISION MACHINING: HOW TO CHOOSE THE BEST COMPANY TO WORK WITH

Cost savings aren’t the only thing a company must consider when searching for the right precision machining company to work with. After all, said projects require extreme attention to detail, and the experience to match. Making decisions based purely on…

PRECISION MACHINING: A GENERAL OVERVIEW

The term “Precision Machining” is a reference to the process that produces many of the objects we use both in our daily lives, and in high-tech industries. The world’s most complex engineering feats require a multitude of precise parts that…

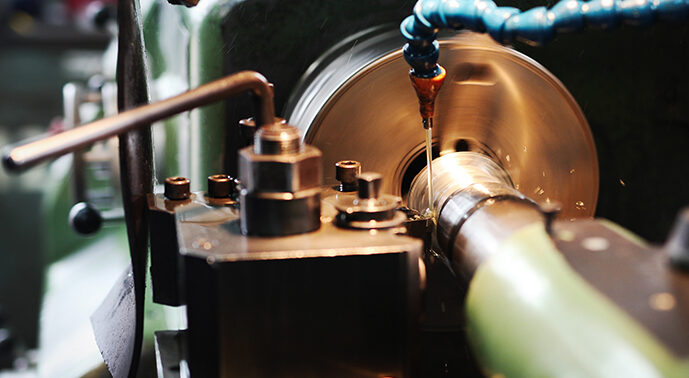

UNDERSTANDING THE CNC TURNING PROCESS

Understanding how the CNC Turning process is achieved can help one better understand the applications for industry. Typically the process involves taking a bar of metal material and securing it in a chuck which is rotated. While this is happening,…