What We Do

Since 1971, B.C. Instruments has played a vital role in serving the needs of clients across the Aerospace, Medical, Nuclear, Plastic Injection Molding, and Electro-Optic industries around the world. We remain committed to our impeccable service as these industries continue to evolve throughout the 21st century.

About Us

B.C. Instruments has been serving customers in the Aerospace, Defense, Plastic Injection Molding, Medical, Nuclear and Electro-Optic industries since 1971. Our head office is just 35 minutes north of Toronto’s Pearson International Airport in the rural community of Schomberg, ON, with an international office based in India.

Our Anti-Harassment and Discrimination Pledge

We pledge and commit to the following:

Treating people with dignity and respect regardless of their gender, race, national or ethnic origin, colour, religion, age, sexual orientation, marital or family status and/or disability

Not tolerating, condoning, or ignoring workplace violence, discrimination or harassment

Being role models and using our voices to raise awareness in making our workplace safe from discrimination, harassment and violence

Doing something about workplace violence and discrimination or harassment when we see or know it occurs and this includes images (graffiti) or verbal slurs or sayings that degrade any group of people or person

Industries We Serve

B.C. Instruments is proud to serve the needs of multiple clients across several major industries. Our commitment to build quality, impeccable service and (most importantly) pinpoint precision is reflected in our work, and we make it a mission to continuously improve upon our existing procedures and technologies in preparation for a rapidly changing tomorrow.

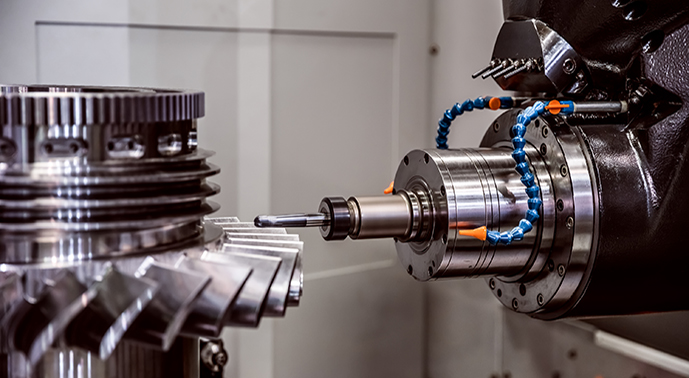

Aerospace

Aerospace

B.C. Instruments serves the Aerospace industry by bringing 40 years of vast experience in build-to-print for OEMs and top-tier clientele. We are proud of our Quality Management System which has been certified to ISO 9001:2015, compliant to AS9100D.

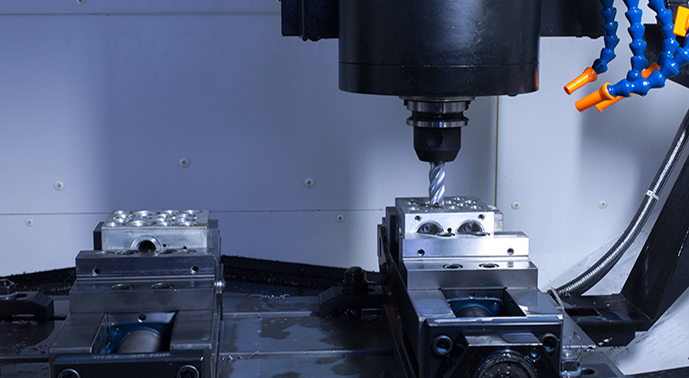

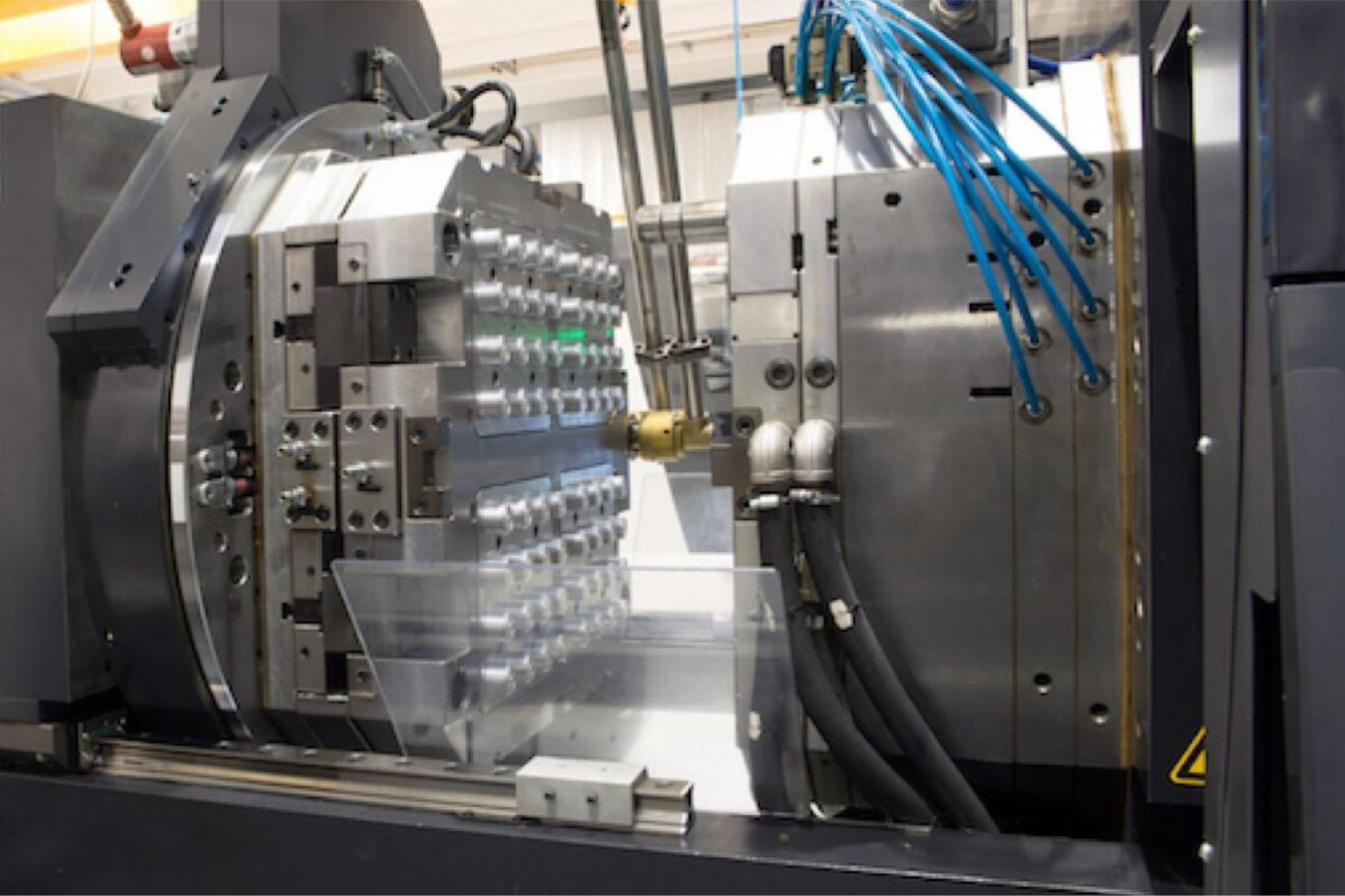

Plastic Injection Molding

Plastic Injection Molding

Our facilities manufacture notable products including Nozzle Tips, Housings, Cooling Inserts, Pistons, Cylinders, Insulators, Manifold Brushings and Mixers, among others from the hot and cold sides of the mold.

Medical

Medical

B.C. Instruments is proud to serve the Medical and Pharmaceutical industries when it comes to improving the health of people around the world.

Nuclear

Nuclear

B.C. Instruments brings over 40 years of experience as a quality subcontract supplier and a leader in manufacturing high quality components and assemblies for the expansion of clean nuclear energy.

Electro-Optic

Electro-Optic

B.C. Instruments utilizes some of the most accurate pieces of equipment to produce Electro-Optic devices and systems across all levels of manufacturing. We are registered under the Controlled Goods Program (CGP) to provide components and technical data that have military or national security significance.

B.C. Instruments Quality

Quality Assurance at B.C. Instruments means more to us than inspection. Utilizing the Organizational Systems Thinking model, we integrate the Management System, Human System and Production System into our Quality Management System. This model assures quality interactions and results through all steps of our Quality Management System, from quotation, job planning, employee development, supplier management, manufacturing, inspection, and documentation through to final product delivery for our customers. We are ready to meet any needs that your company may require while supporting the quality products we manufacture.

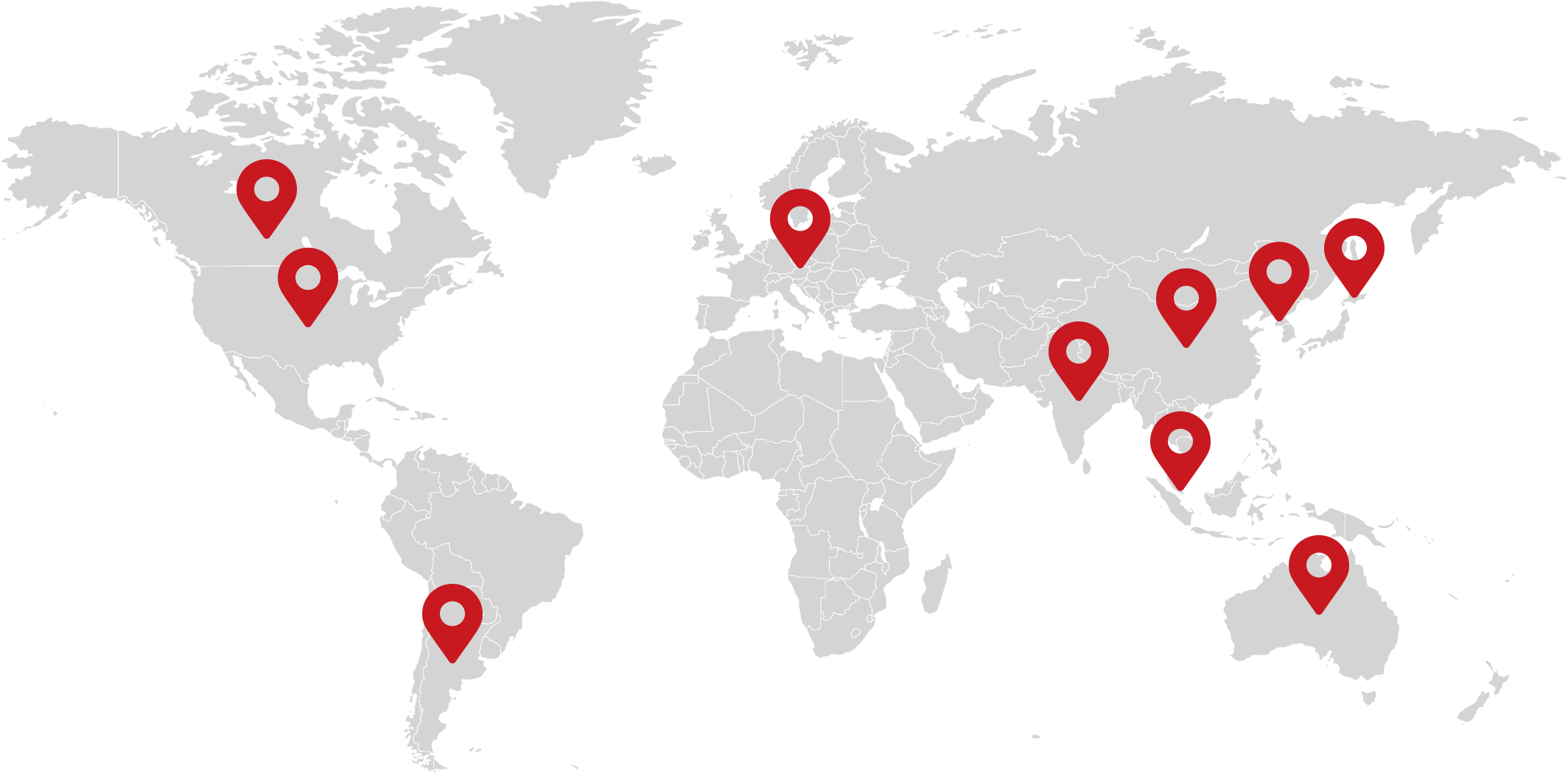

B.C. Instruments at Scale

Having grown from a small shop in a one car garage, B.C. Instruments is now a Global Supplier currently operating out of 6 manufacturing facilities in Ontario, Canada and one in Gujarat, India. We’re busy serving customers around the world including Canada and the United States, Europe, China, India, Singapore, Korea, Australia, Argentina and Japan. Customer Kan-Ban and Stocking Agreements gives B.C. Instruments the ability to fulfill orders within a 24 hour turnaround if required.

Check out our blogs to learn more!

The Prototype Phase, And How We Approach IT

5 COMMON PROBLEMS WITH CNC MACHINES, AND HOW WE FIX THEM

CNC MACHINING & THE SKILLS REQUIRED BY OUR STAFF

The Machining Company

Check out some of our career opportunites

Contact Us Today!