Our Capabilities

- CNC Milling

- CNC Turning

- Electron Beam Welding

- Exotic Materials

- High Efficiency Machining

- Laser Engraving

- Outside Services

- Rapid Prototyping

- Secondary Operations

- Ceramic Machining

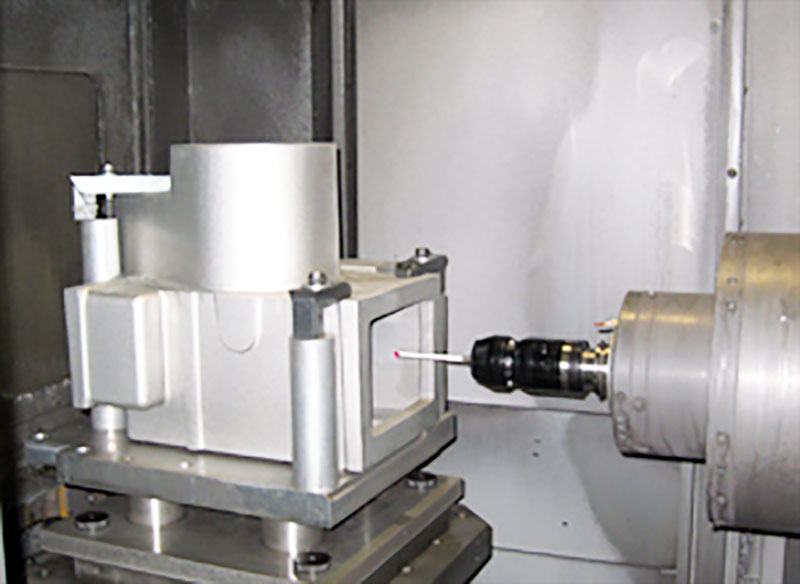

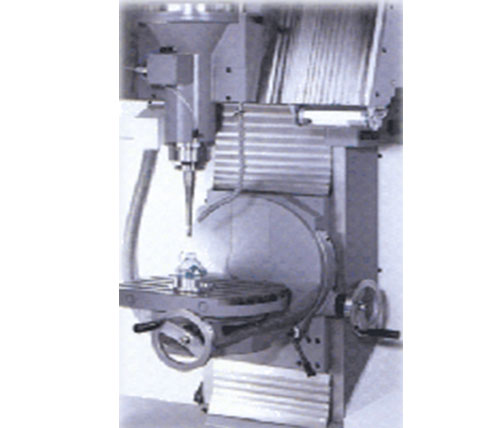

CNC Milling

CNC Milling

B.C. Instruments utilizes palletized Milling centres to provide competitive pricing in the global marketplace.

Our Mori-Seiki 5-axis Vertical Mill-Turn machining centre is equipped with an 8 pallet pool and 180 tool ATC. This high speed, high accuracy machine enables us to maintain multiple setups with minimal changeover time which provides increased machine utilization and unattended production. Difficult part geometries requiring multi-axis machining can be produced in one setup, thereby eliminating the inaccuracy of multiple setups. This provides our customers with the confidence and trust in our ability to deliver quality parts on time at a competitive price.

The 4-axis, horizontal machining centres are equipped with Renishaw probes, enabling us to accurately locate casting datums or pre-fabricated parts efficiently. The tool breakage detection feature, high pressure coolant and 7 pallet pool transfer system further enhances our operational performance.

Our team of highly skilled setup personnel are supported by a proactive and knowledgeable engineering group using the latest Cad Cam software. With our process engineering ability, we have been providing our customers with DFM support (design for manufacturing) for over a decade. Most of the product lifecycle costs are committed at the design stage and keeping our customer’s costs as low as possible at this phase is essential in strengthening our relationship with our customers.

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

CNC Turning

CNC Turning

We have 32 CNC turning machines including state of the art Tsugami and Nakamura Tome Mill/Turn centers as well as a range of Hardinge Super Precision Hard Turning Machines. Our inventory also includes Mazak, Deckel Gildemeister and Mori Seiki equipment.Our specialty is intricate internal features and extreme tight dimensional tolerances.

Vice President, Section Manager

Small Diameter Turning

905-939-7323 - Ext 371

robw@bc-instruments.com

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

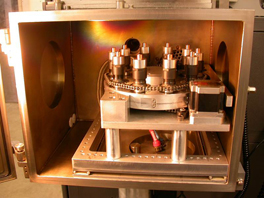

Electron Beam Welding

Electron Beam Welding

B.C. Instruments has two Electron Beam Engineering EB Welders with a 12 inch cube vacuum chamber. Our personnel received extensive training at the manufacturer’s facility and on site at BCI. This equipment allows us to join dissimilar metals in a vacuum with no filler material and minimal part distortion.

Model 512 Beamer

Chamber 12 x 12 x 12

Weld penetration in steel .025 mm to 18.0 mm

Weld times from 0.1 sec to 999 sec

Speed 760 mm per minute

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

Exotic Materials

Exotic Materials

In addition to conventional materials, we are experienced in working with such exotic materials as Hy-Mu 80, Titanium, Inconel 718, A-286, Monel, Haynes Alloy 41 (Rene 41), Metal Matrix Composites (MMC) and most grades of Ceramic. We also have experience machining Beryllium Copper for both Aerospace and Commercial Industries; all processes tested and maintained to meet company standards set well under the current exposure limits required by the Ministry of Labour's Occupational Health & Safety Act.

41 Proctor Road

Schomberg, Ontario

L0G 1T0, CANADA

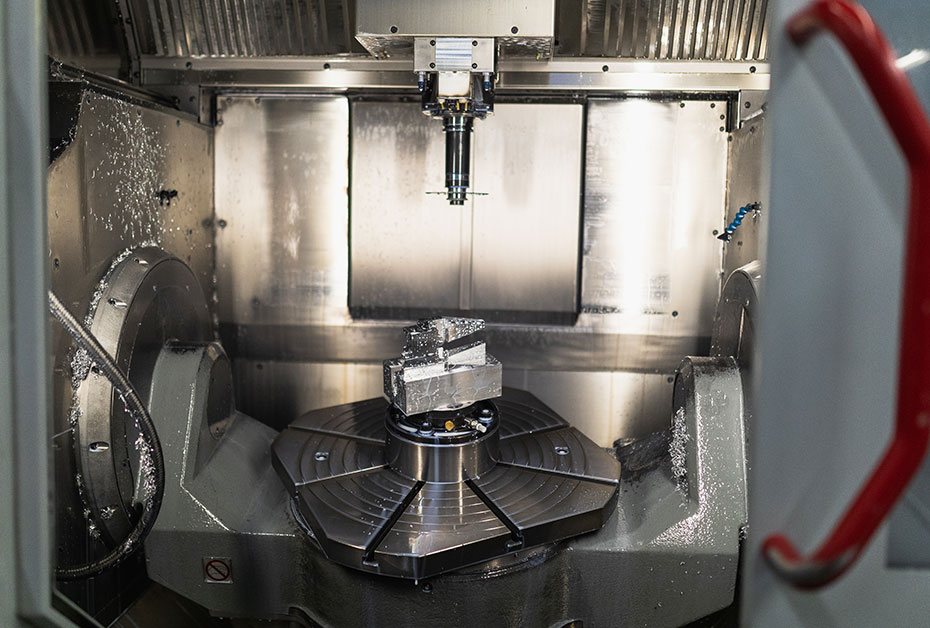

High Efficiency Machining

High Efficiency Machining

Our High Efficiency Machines use zero point clamping interfaces with repeatability to 0.005mm which can be engineered to accommodate modular automation cells.

We make use of a number of machines that utilize high speed spindles, high pressure coolant and constant chip evacuation to machine components at high metal removal rates. This equipment incorporates the use of Robotics and automated CMM inspections and feedback to the CNC controls which allows for 24 - 7 lights out capability, while maintaining precise dimensional control of components being manufactured.

Hard Turning

Hembrug Mikroturn 100

Vice President, Section Manager

Small Diameter Turning

905-939-7323 - Ext 371

robw@bc-instruments.com

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

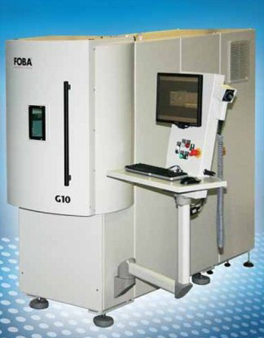

Laser Engraving

Laser Engraving

B.C. Instruments uses 2 of the FOBA G10 Laser Engraving Machines. These state of the art machines provides the following benefits:

- 2D part marking

- 3D deep engraving

- 100 Watt, 1064nm laser

- 120 x 120mm2 Engraving field

- 250 x 250mm X/Y axis table. 300 x 300mm travel. Max load 50kg

- Z axis. 500mm travel

- Rotary axis

- No contact processing. Clamp free work holding

- Graphic import of multiple file types.

The Fiber Tower Marking System manufactured by PTG Industries features independent components that include q-switched fiber laser, scan head, PCI control board, and graphic-based programming software. It can perform applications such as 2D symbologies and linear barcodes, OCR code marking, and on-the-fly marking and is capable of printing alphanumerics, logos, schematics, and graphics.

Vice President, Section Manager

Small Diameter Turning

905-939-7323 - Ext 371

robw@bc-instruments.com

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

Outside Services

Outside Services

We have built many productive relationships with outside vendors and process houses to provide many services, including:

- EDM

- Grinding

- Heat Treating

- Nickel-ceramic Coating

- Titanium Nitriding

- Carbide Brazing

- NDT (Non-Destructive Testing)

- Electro less Nickel Plating

- Nitriding

Vice President, Section Manager

Small Diameter Turning

905-939-7323 - Ext 371

robw@bc-instruments.com

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

Rapid Prototyping

Rapid Prototyping

B.C. Instruments Rapid Prototyping Technology Process

- Evaluate customer drawing requirements

- Program & machine complete to customer print without outside engineering support

- Perform a final inspection prior to shipping

- Target lead-time of two days

- 3D Printing

Our Rapid Prototyping equipment includes two 2 Mazak Nexus CNC Lathes with Mazatrol conversational programming system as well as a Haas VF-2 machining center.

Vice President, Section Manager

Small Diameter Turning

905-939-7323 - Ext 371

robw@bc-instruments.com

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

Secondary Operations

Secondary Operations

We have in-house capacity to machine parts requiring Gundrilling, Hard Milling and Turning, Honing, Wire EDM, Cylindrical Grinding, Laser Engraving, Lapping, Brazing and Electron Beam Welding. We are set up to install various types of hardware and bond components using structural adhesive films and liquids to military and federal specifications. In addition to this we have the capability to perform extruded media deburring.

Vice President, Section Manager

Small Diameter Turning

905-939-7323 - Ext 371

robw@bc-instruments.com

Vice President, Section Manager

Large Diameter Turning, Mold

905-939-7323 - Ext 343

brucec@bc-instruments.com

Ceramic Machining

Ceramic Machining

B.C. Instruments offers superior services and practical solutions for engineered materials needs. We have the ability and technology to manufacture low, medium and high volume components with complex geometries and assemblies requiring tolerances as close as three microns.

We consistently advance and rethink the manufacturing of engineered materials from offering advice, solutions, changes and/or modifications to clients’ components and products, to seeking out and embracing the latest and most effective technology to work with.

Our full spectrum manufacturing supports and services engineered materials from ceramics such as alumina and zirconia, silicon nitrate, glass, graphite and composite materials to precious stones, which provides optimum benefit to our clients in the medical and space sciences, and oil, gas, and nuclear industries.

Section Manager

Engineered Materials

705-329-3616 - Ext 223

scott@bc-instruments.com