B.C. Instruments is proud to serve the Medical and Pharmaceutical industries when it comes to improving the health of people around the world. It all starts with our design phase which makes our services readily available from the onset, allowing clients to work alongside us as we design for the manufacturing process, while maintaining cost-efficiency. Our ability to 3D print breadboard parts and prototypes gives us an advantage when it comes to accelerating the development stage. We then utilize our ISO Class 7 clean room to manufacture and assemble components before final cleaning and packaging at our ISO Class 4 bench. B.C. Instruments specializes in the manufacture of components for spectrometers, as well.

Case Studies

Western Formula Racing

LONG TERM CLIENT

LIBURDI

Our Blogs

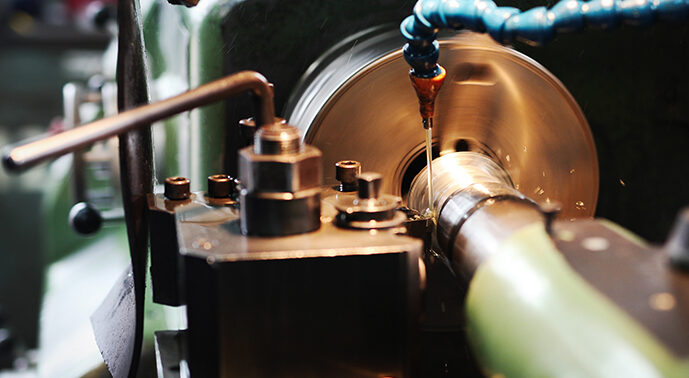

PRECISION MACHINING: HOW TO CHOOSE THE BEST COMPANY TO WORK WITH

PRECISION MACHINING: A GENERAL OVERVIEW

UNDERSTANDING THE CNC TURNING PROCESS

Other Industries

Aerospace

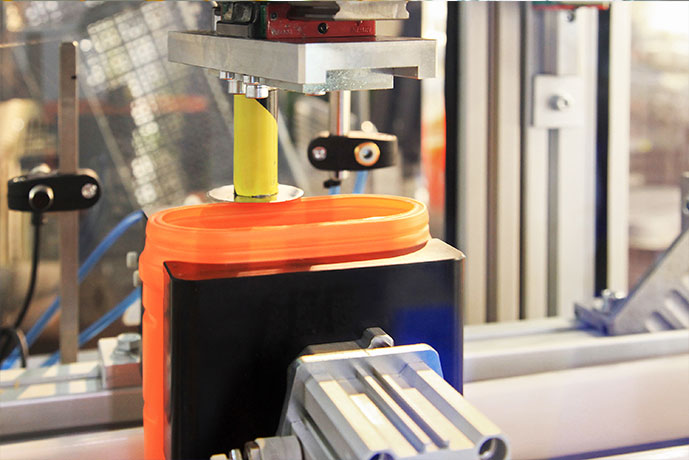

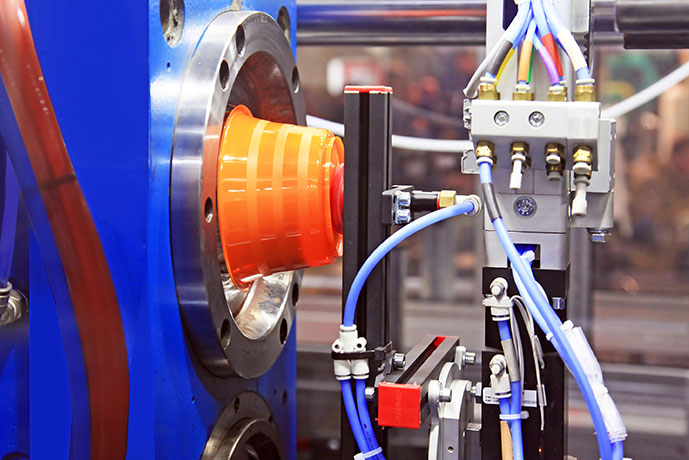

Plastic Injection Molding

Nuclear