Our Vision

Our Vision at B.C. Instruments is to be recognized as the supplier of choice for precision machining solutions by our selected customers and as the employer of choice for those who embrace a culture of lifelong learning and a relentless drive to improve.

Our Mission

Our mission at B.C. Instruments is to create productive and lasting relationships based on mutual trust and respect among ourselves, our customers, shareholders, suppliers, and surrounding communities.

B.C. Instruments has been serving customers in the Aerospace, Plastic Injection Molding, Medical, Nuclear, Defence and Electro-Optic industries since 1971.

Our Strategy

Our strategy at B.C. Instruments is to utilize the process of continuous improvements through learning in our daily activities to create positive changes within all levels of our organization.

Our History

From our beginnings, we have grown to our present size of 60,000 square feet with 158 employees

Industries We Serve

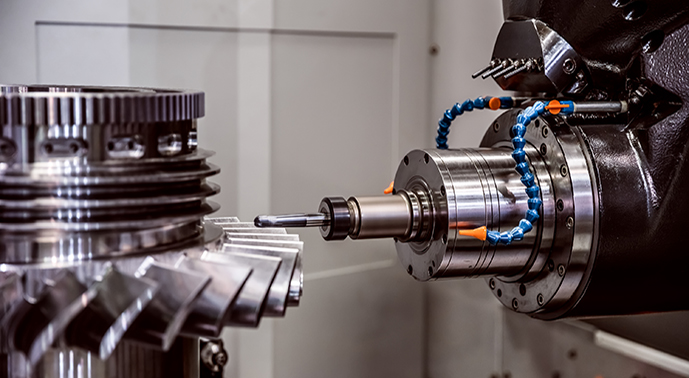

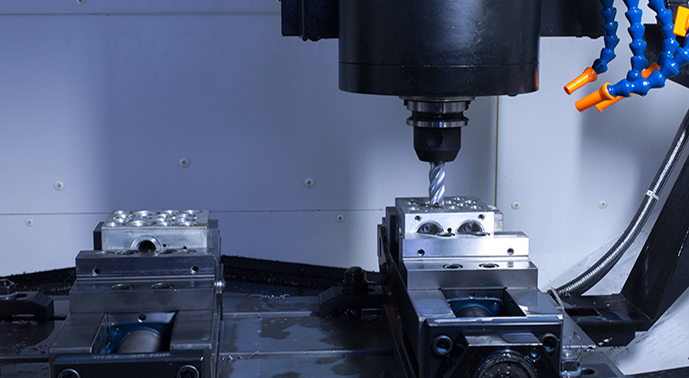

B.C. Instruments is proud to serve the needs of multiple clients across several major industries. Our commitment to build quality, impeccable service and (most importantly) pinpoint precision is reflected in our work, and we make it a mission to continuously improve upon our existing procedures and technologies in preparation for a rapidly changing tomorrow.

Aerospace

Aerospace

B.C. Instruments serves the Aerospace industry by bringing 40 years of vast experience in build-to-print for OEMs and top-tier clientele. We are proud of our Quality Management System which has been certified to ISO 9001:2015, compliant to AS9100D with CGP approval.

Learn More

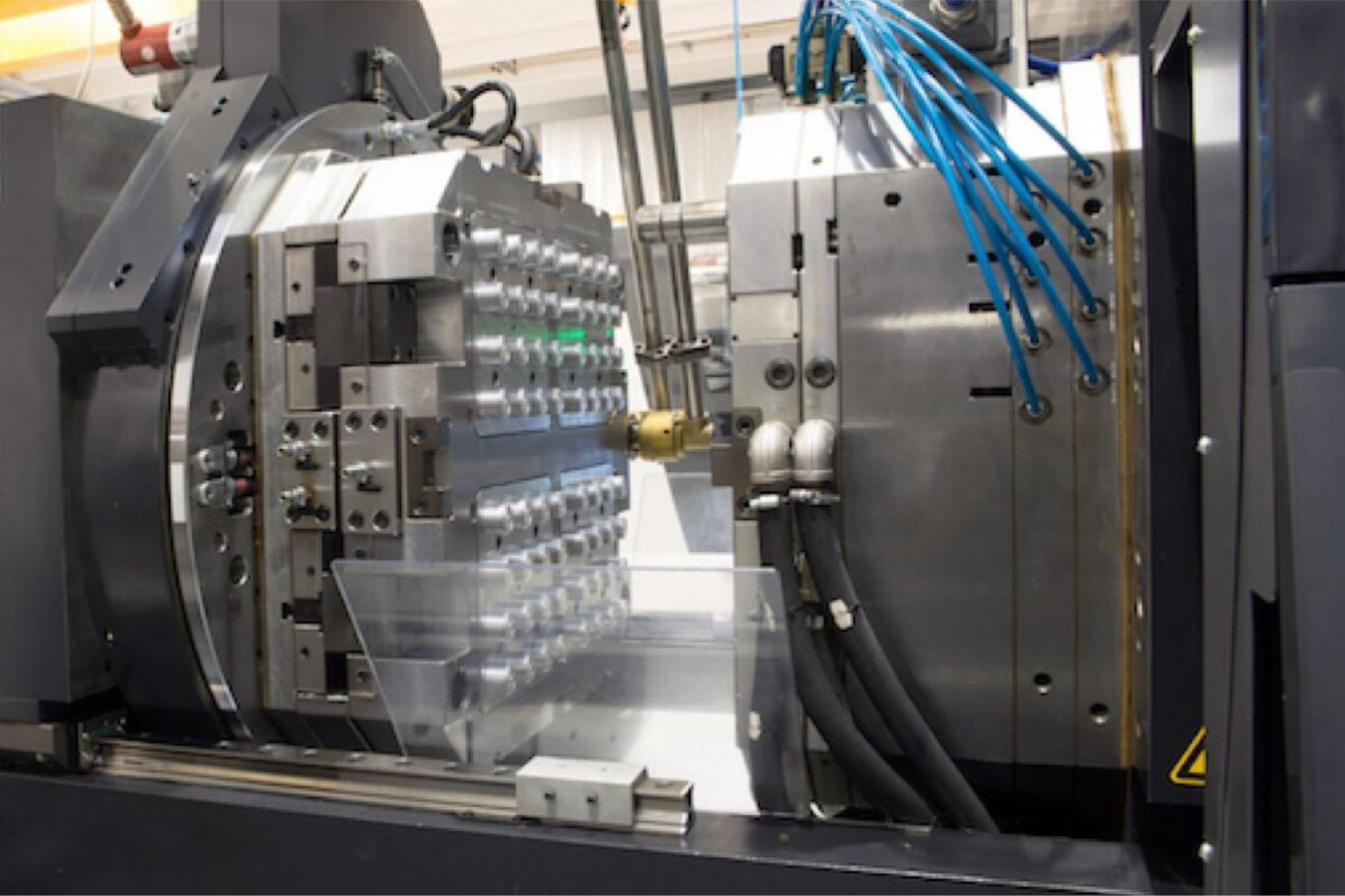

Plastic Injection Molding

Plastic Injection Molding

Our facilities manufacture notable products including Nozzle Tips, Housings, Cooling Inserts, Pistons, Cylinders, Insulators, Manifold Brushings and Mixers, among others from the hot and cold sides of the mold.

Medical

Medical

B.C. Instruments is proud to serve the Medical and Pharmaceutical industries when it comes to improving the health of people around the world.

Nuclear

Nuclear

B.C. Instruments brings over 40 years of experience as a quality subcontract supplier and a leader in manufacturing high quality components and assemblies for the expansion of clean nuclear energy.

Electro-Optic

Electro-Optic

B.C. Instruments utilizes some of the most accurate pieces of equipment to produce Electro-Optic devices and systems across all levels of manufacturing. We are registered under the Controlled Goods Program (CGP) to provide components and technical data that have military or national security significance.

Leadership Team

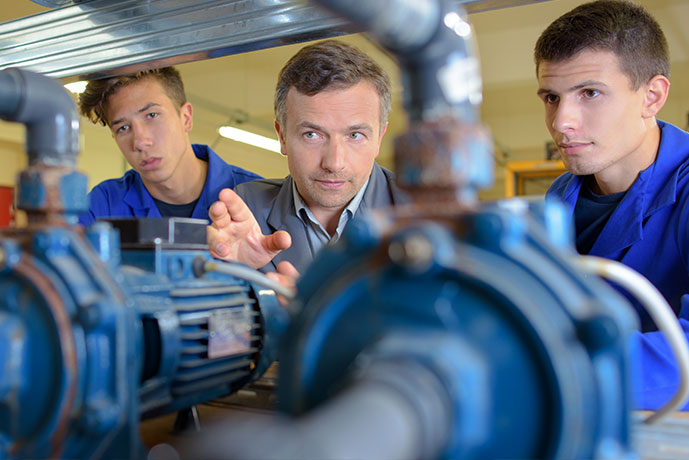

Becoming a leader in such a technologically complex environment means having the right team members at the forefront to lead the charge. Our talented and skilled leadership team knows the ins and outs of the major industries we work with, and they have been responsible for making B.C. Instruments the power player that it is today.

Roger Conzelmann

CEO

Roger Conzelmann

President of BCI

Roger Conzelmann son of founder Bruno Conzelmann, began his career at BCI in 1980. Roger started out on the shop floor by working his way up through a variety of roles including setup, programming and team leadership before taking over the role of President in 2005. Roger has now taken on the role of CEO after retiring in 2023.

Bruce Conzelmann

Vice President

Section Manager - Aerospace

Bruce Conzelmann

Vice President

Section Manager - Aerospace

Like his brother Roger, Bruce Conzelmann started out at BCI in 1979 on the shop floor before working his way through setup, programming, team leadership and other critical roles. Bruce currently serves as Vice President since 2005, as well as Section Manager to the Aerospace Division since the 1990s.

Rob Wheeler

Vice President

Section Manager - Plastic Injection Molding

Rob Wheeler

Vice President

Section Manager - Plastic Injection Molding

Rob Wheeler began his tenure at BCI in 1982, after briefly working for Bell Canada. Rob worked his way up from the shop floor to his current roles as Vice President, to which he was appointed in 2005, and Section Manager for the Plastic Injection Molding division since 1995.

Mike Spence

Head of Quality Assurance

Mike Spence

Head of Quality Assurance

Mike Spence joined BCI in 2000 as the Manager of Quality Assurance, which is the role he holds to date. Prior to joining the company, Mike worked at Litton Industries for over fifteen years in a quality assurance role. In addition to managing the QA department, Mike looks after all facilities and property maintenance at BCI.

Uma Mallik, P.Eng

Section Manager —Nuclear

Debbie Martyn

Controller

Scott Young

Section Manager – Life Sciences

Scott Young

Section Manager – Life Sciences

Scott joined BCI in 2023 as plant manager and soon took on the role of Section Manager of our Engineered Materials Machining Division. Scott began his career as a Tool and Die Maker servicing many industries and has managed manufacturing facilities around the world with up to 400 employees.

B.C. Instruments India

Get to know our global operations.

B.C. Instruments operates internationally out of our India division where we manufacture and supply top quality components and other products for Aircraft & Aerospace, Electro-Optic, the Medical industry and many more.

B.C. Instruments in the News

The Prototype Phase, And How We Approach IT

5 COMMON PROBLEMS WITH CNC MACHINES, AND HOW WE FIX THEM

CNC MACHINING & THE SKILLS REQUIRED BY OUR STAFF

Join our team today!

If you enjoy the thrill of a constant challenge and the opportunity to continuously advance your skills and career while growing alongside an industry-leading company, we’d love to hear from you. Apply today for our open positions and come be a part of our dynamic team.