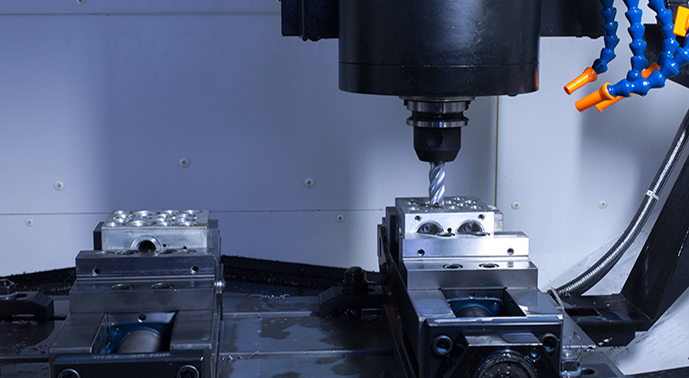

Technology has come a long way in our field, but there’s simply no substitute for a skilled CNC machining operator who knows the ins and outs of the job. Like any skilled trade, CNC operators must possess and demonstrate several key skills required to succeed at B.C. Instruments.

Due to the highly precise nature of the parts we manufacture for some of the world’s most demanding industries, second-best is simply not acceptable. Here are the skills our CNC operators apply every day at BC Instruments.

CAD/CAM KNOWLEDGE

CNC machining is a process driven primarily by CAD/CAM technology, which stands for “Computer Aided Design” and “Computer Aided Manufacturing,” respectively. Anyone who has worked with this type of software before knows how precise the designs must be. This is where the process starts, and if the design is wrong, the end product will also be wrong, even if it’s off by a few millimeters.

Our operators know how to navigate this interface to guarantee that designs are double-checked before a run is produced. Their experienced eyes can spot errors and defects in the design before the final product is created, thereby saving time and money. This is absolutely vital when it comes to sticking to strict deadlines.

TRADE SKILLS

It’s important for our operators to understand all the processes of CNC machining, including the hands-on work. This means possessing knowledge of physical skills such as manual grinding and drilling, which are vital for many product runs. They must also be able to check and verify (and if necessary, check again) product dimensions using precision tools. This is mostly done in the prototype phase where any and all defects and kinks are worked out before the final run is produced.

TECHNICAL KNOWLEDGE

Our operators may know the software, and they may be good with their hands, but gray matter is just as important. These skilled workers can read technical blueprints as if they were travel brochures, not to mention technical instructions and models. Without a solid understanding of these fundamentals, it’s impossible to move onto the crafting process without error.

Those proficient in math tend to have a field day with CNC machining. This is especially true when it comes to calculating schematics to ensure correct sizes, shapes and designs of target products. For example, B.C. Instruments serves the Nuclear Energy industry, so one can imagine the level of peak precision required for a product run.

We are proud of our CNC operators who continue to form the backbone of our operations at BC Instruments. With decades of experience, we know what our clients require, and failure is not an option. For more information on our CNC machining services and how they can serve your company during its next production run, contact B.C. Instruments today.