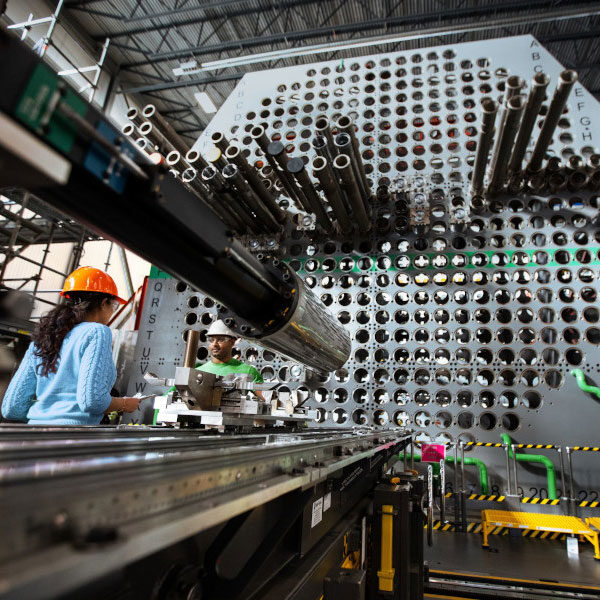

B.C. Instruments brings over 40 years of experience as a quality subcontract supplier and a leader in manufacturing high quality components and assemblies for the expansion of clean nuclear energy. Some of our manufactured components include Nuclear Class 1, 2 and 3 components, plus assemblies such as Fuel channel, Feeder connections, Feeder support, Feeder I & C, Fuelling machine, fuel handling and other nuclear components and assemblies (Shield Plug assembly), Channel Closure plug assembly, Adaptor and Thermowell, Hubs, Flange, Seal Rings and Cap screws, Journal rings, Bearing & Shielding sleeves, guide tube clamp-on and immersion assemblies, snout plugs, magazines and ram assemblies.

Since 1971, B.C. Instruments has provided supplies and sub-assemblies for the following CANDU Generating Station Projects:

Bruce Generating Station

Darlington Generating Station

Point Lepreau Generating Station

Gentilly Generating Station

Wolsong Projects

Cernavoda Projects

Embalse Projects

Qinshan Project

Ontario, Canada

Ontario, Canada

New Brunswick, Canada

Quebec, Canada

South Korea

Romania

Argentina

China

Case Studies

Western Formula Racing

LONG TERM CLIENT

LIBURDI

Here is a list of memberships/associations we belong to

CSA-N285.0 (TSSA Cimages/N285 0 Certificates.pdfert.)

ASME Section III

CSA Z299.2 (CANPAC Approved)

ISO9001:2008 (registered) / AS 9100C

OCNI

Alliance for Enterprise Excellence

Our Blogs

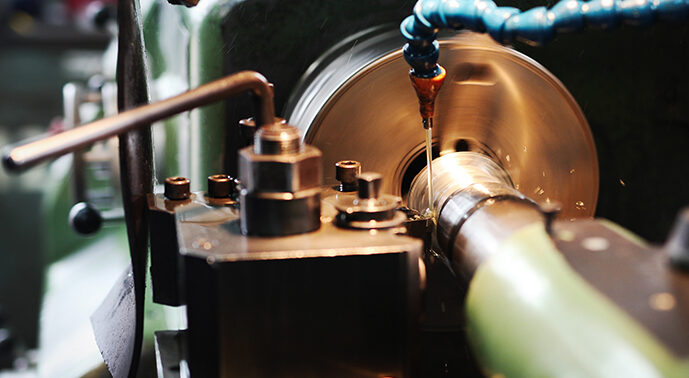

PRECISION MACHINING: HOW TO CHOOSE THE BEST COMPANY TO WORK WITH

PRECISION MACHINING: A GENERAL OVERVIEW

UNDERSTANDING THE CNC TURNING PROCESS

Related Industries

Aerospace

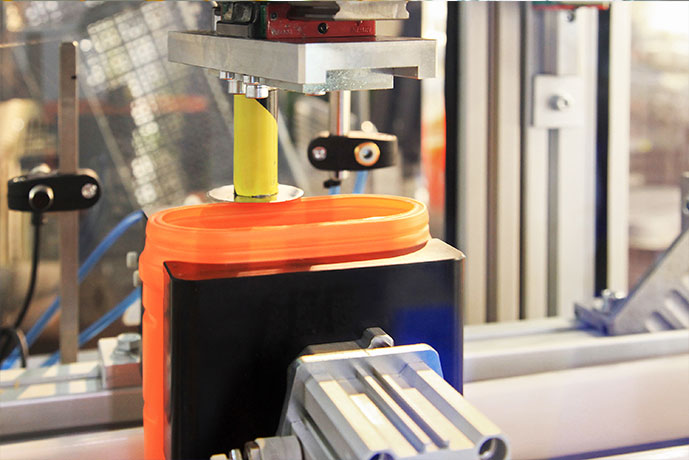

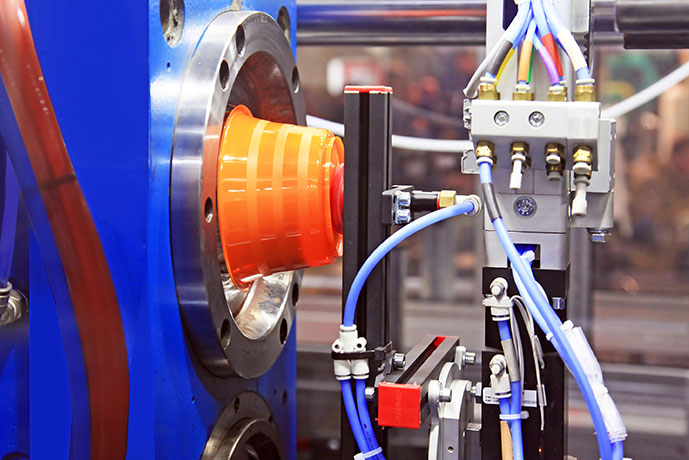

Plastic Injection Molding

Medical