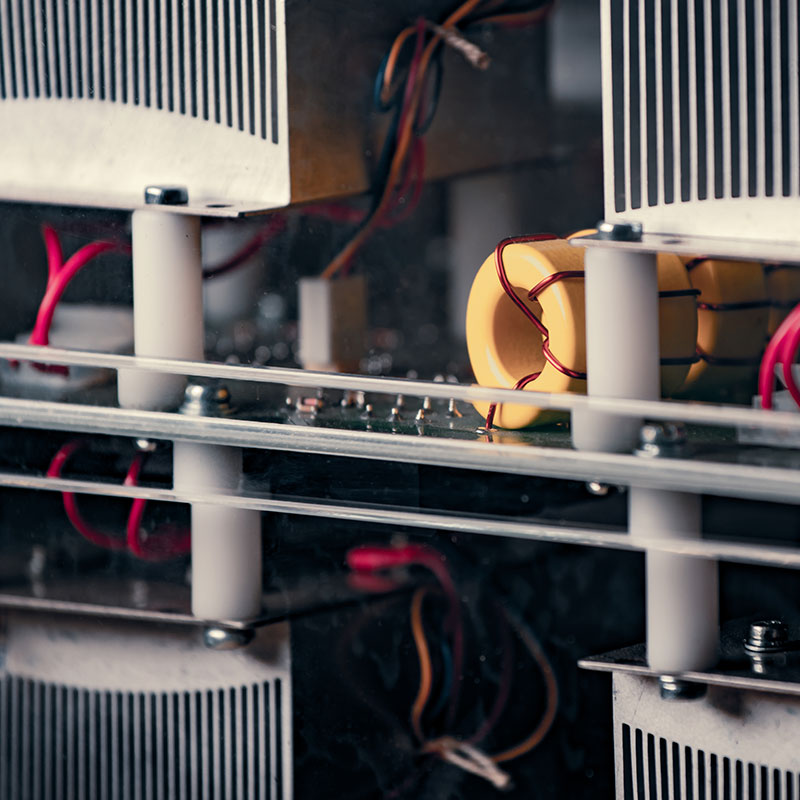

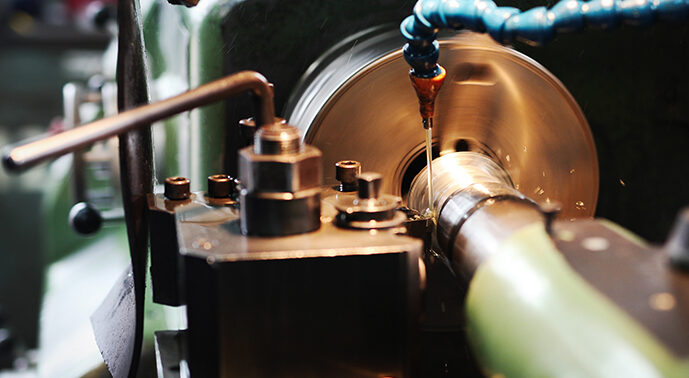

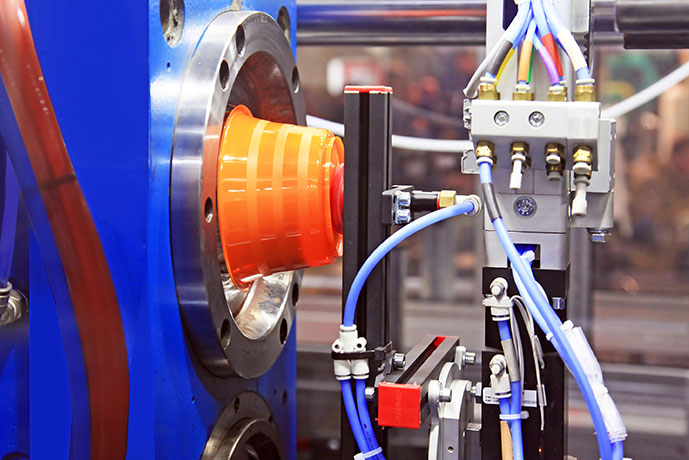

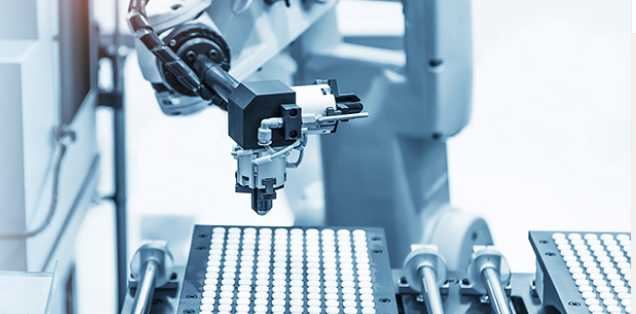

B.C. Instruments utilizes some of the most accurate pieces of equipment to manufacture Electro-Optic devices and systems. Our multi-axis high precision department manufactures within a climate controlled environment and is able to machine with tolerances as high as 0.008mm in a 600mm envelope. We have a wide array of 5-axis equipment with pallet pools and integrated automation, and we inspect our work to be sure it adheres to strict industry leading quality standards. For larger high precision components, we utilize internal capabilities to vibrator stress relief materials from 17-4PH, 6061 T6 aluminum, and other various materials in a free state. We support all levels of manufacturing from prototyping for new product introduction (where our team can support designers with the most cost effective engineering inputs for manufacturability) to production volumes with large multi-piece fixtures that are engineered to ensure maximum runtimes at the most cost effective part price. B.C. Instruments excels at project management from start to finish with support for customer programs with in house machining, relationships with choice suppliers for various finishing processes, and the added capability of internal assemblies. B.C. Instruments is also registered under the Controlled Goods Program (CGP) to provide components and technical data that have military or national security significance, if required.

Case Studies

Western Formula Racing

LONG TERM CLIENT

LIBURDI

Our Memberships

Alliance for Enterprise Excellence