No single piece of technology exists that isn’t riddled with at least a few glaring oversights, design flaws or software bugs. CNC machines are no different. At BCI, our CNC machines are the lifeblood of our operations, which means we won’t tolerate anything but the best performance at all times. After all, one mistake – one deviation in our production process means our clients suffer, and that’s not something we tolerate.

So, how does BCI navigate these pitfalls and prevent them from popping up during our production process? First, we need to identify the five most common problems with CNC machines, before we generate fixes for them. Here’s what they are, and how we deal with each one.

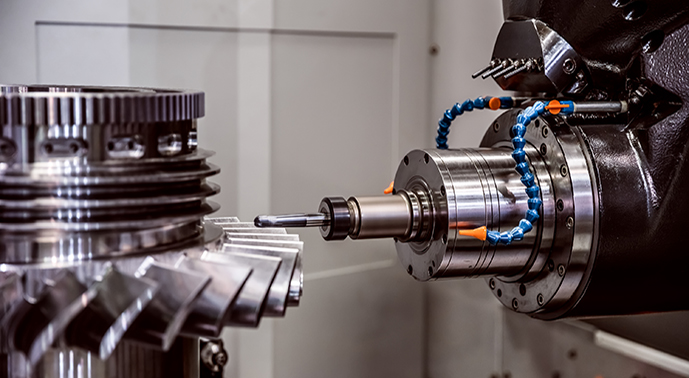

#1) CHUCKS AND FIXTURES

There are times when chucks and fixtures on CNC machines cannot adequately hold the machined piece. In this case, vibrations and shifting can occur which can spell big trouble for the production process. Our solutions are rudimentary, and usually involve an elevated approach to the problem. For instance, we first check to make sure the piece has indeed been secured correctly before moving onto other things.

We check to make sure the grips can adequately hold the piece, we check the hydraulic pump and pressure, and we check to make sure other technical issues like foot switch problems or lubricant issues aren’t at play. Since improperly gripped machine parts can lead not just to damage, but operator injury as well, we make absolutely sure our CNC machines clutch their materials correctly, the first time.

#2) OVERHEATING

Due to the extremely high volume orders we take from our clients, our CNC machines are running almost constantly. This means overheating is a factor that we must take into account. Thankfully, we plan ahead on this to make sure all of our machines are working in tip-top shape. It’s important to remember that the basic function of CNC machining means that heat will be a natural result. Our machine tools can hit temperatures as high as 150 degrees, or more. Care must be taken to make sure that this doesn’t affect our machine, or the part in question.

Cleanliness is key, and we make sure our machines are thoroughly wiped down, and that all dirt and debris have been removed. Metal shavings can contribute greatly to overheating, which is why we adhere to a strict cleaning schedule. Overheating can occur from other sources, however. Running a CNC machine at high RPMs for a prolonged period of time means adhering to some standards.

#3) OPERATOR TRAINING

Human error is a constant in any business, but it can be mitigated through proper training and adherence to guidelines. In the case of CNC machining, this means training our operators on how to use the CNC software which runs each machine, plus a thorough understanding of G and M codes, setup and the inputting of data.

We consider this to be of maximum importance, and it shows in the skill of our operators. Machines can only do the job, but the human element is what counts. This is how we continue to please clients the world over, throughout a multitude of important business sectors.

#4) POWER SUPPLY ISSUES

Believe it or not, sometimes the most common problem is also one of the most basic. CNC machines are quite complex, and they can be hobbled by power supply problems. This can often take the form of incompatibilities between the machine and the power socket in question.

We make sure that our CNC machines are running on compatible power supplies with correct voltage settings required for the input side. If we do experience power supply issues beyond that, we bring in certified electricians to make sure there are no faults to our power supplies on the opposite end of the connection. Stable power flow is an absolute must during a CNC machining run, and we do regular checks to make sure ours are running at peak efficiency.

#5) WRONG TOOLS OR SETTINGS

This is a common issue with many precision machining companies, and it really shouldn’t be. In order to successfully complete a production run, one must choose the appropriate cutting tools and settings before the job begins. Failure to do so can result in damage to the finished product in the form of burn marks, rough edges and corners, or visible cutter marks, all of which are unacceptable.

Thankfully, BCI is ahead of the curve on this issue, thanks to over 40 years of experience in the business. Still, it is considered one of the biggest problems faced with CNC machines. The solution lies in the planning stages. Make sure to determine early on the best tool for the job, and do a trial run just to make sure everything is Okay. If not, one may be wearing out their tools faster than anticipated, while ruining their client’s job in the meantime.

For more information on how BCI’s attention to detail and quality excellence has made us a prime player in the Precision Machining industry, please contact us today.